Cascaded thermocline storage with metal wool gets test: HYBRIDplus

Three years ago, Abengoa thermal energy storage engineer Cristina Prieto exchanged the relatively secretive world of commercial CSP for academia.

Now, as the professor for a newly created thermal energy storage discipline at the School of Engineering at the University of Seville, she can be creative at the research level.

From the paper Thermal energy storage (TES) with phase change materials (PCM) in solar power plants (CSP) Concept and plant performance in which Abengoa’s thermal storage expert Cristina Prieto proposed a cascaded thermocline

Returning to academia enabled her to leverage her experience in thermal energy storage to innovate an entirely new storage concept based on four different phase-changing materials (PCM) cascaded in series.

Prieto is now coordinating the EU’s $3 million, 4-year HYBRIDplus project involving three universities and four businesses, which began work at the end of 2022 to demonstrate her concept over the next four years.

“At Abengoa, we focused on high TRL for our commercial plants, right? Now in the university, I have more freedom; to think and invent at a lower TRL,” Prieto explained.

“This is a new concept that has not been tested before. Instead of storing the heat in the conventional two molten salt tanks, we use PCMs, which store the energy as latent heat with higher energy density than sensible heat systems.”

Referring to the nine technology readiness levels (TRL) that measure the maturity of new technologies from concept to commercialization, she added, “But I think we will be ready to go very fast up to TRL 9, for process heat applications, for example.”

Two innovations are to be tested in this thermal energy storage using PCMs. First, it invents a cascaded form of a thermocline. And it will trial low-cost metal wool to increase its thermal efficiency.

A cascaded thermocline

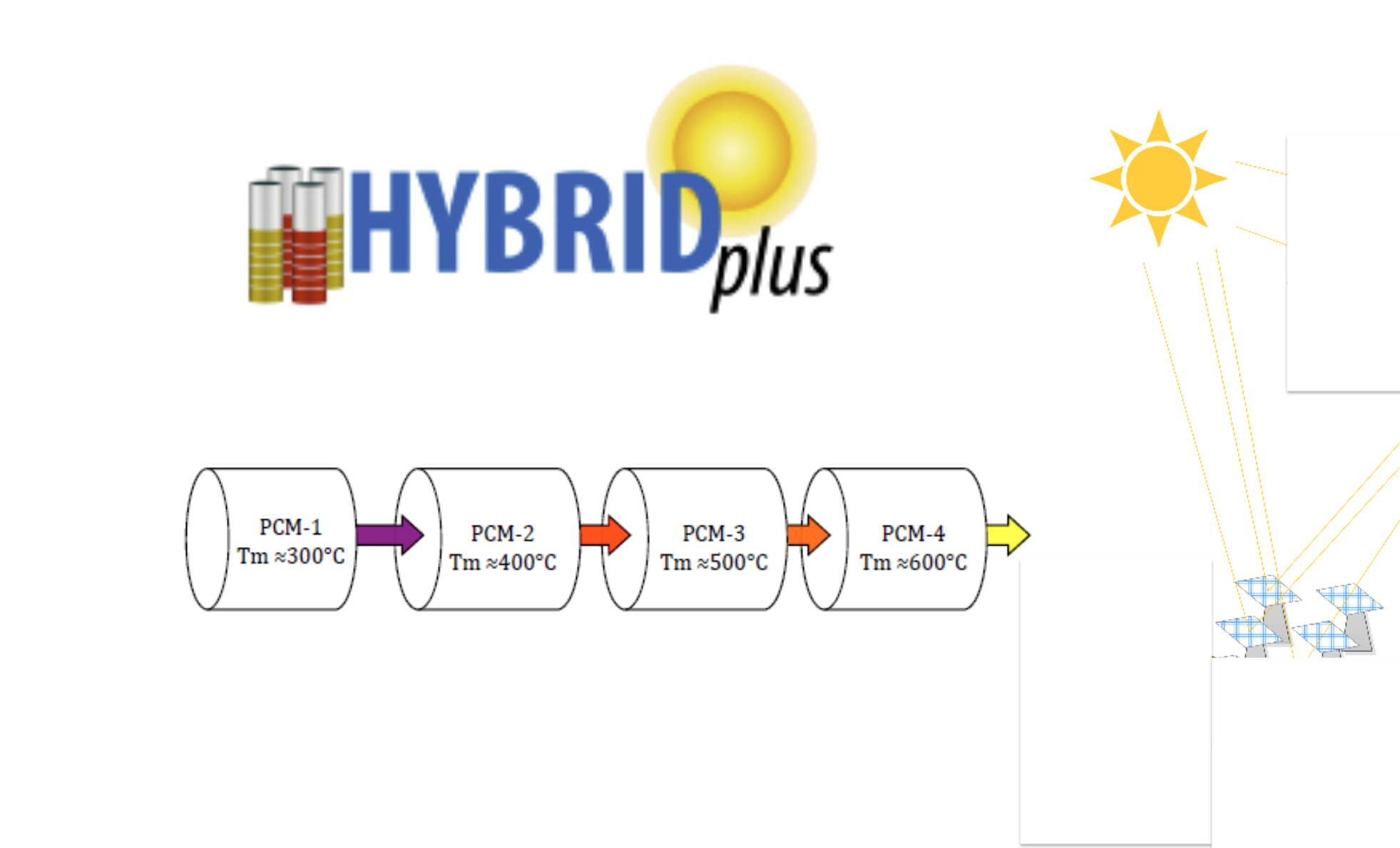

The HYBRIDplus project will leverage the melting points of 4 different PCM, ranging from 300°C to 600°C, held in four separate modules arranged in series inside a tank. In sequence, the heat transfer fluid is cascaded through each module through a central pipe surrounded by each of the four PCM, creating a sort of thermocline.

HYBRIDplus four PCMs from 300°C to 600°C

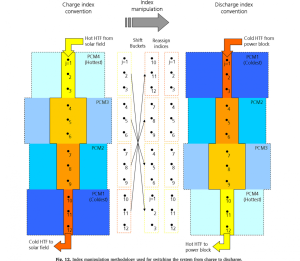

Single tank – thermocline – thermal storage is investigated for its potential to cut costs by eliminating the need for a second cold tank after heat is extracted. But the region of mixed temperatures in the middle (“the thermocline”) risks reducing its thermal efficiency.

In four separate modules, four different chemistry mixtures create this new “cascaded” thermocline. The separation solves the practical problem of thermocline storage as there is no risk of temperature mixing.

“You are trying to create a cascade to reduce the difference between inlet and outlet temperature during charge and discharge,” Prieto explained.

“Using the heat from the phase change during the heat exchange, a hysteresis cycle appears between charge and discharge. This hysteresis limits the maximum temperature at which the system can discharge. To reduce it and get as close as possible to nominal conditions, we use the cascade concept. Each storage module is selected with a different melting point of the PCM, implementing in this way the cascade tank.”

The hysteresis cycle refers to how PCMs absorb and release a large amount of heat during phase changes.

Low-cost metal wool to be tested

Inside each module, metal wool will be densely arranged throughout the liquid molten salt of each PCM surrounding the pipe containing the heat transfer fluid.

A lab test of thermal wool, demonstrating changing direction by layer to spread heat evenly through the PCM

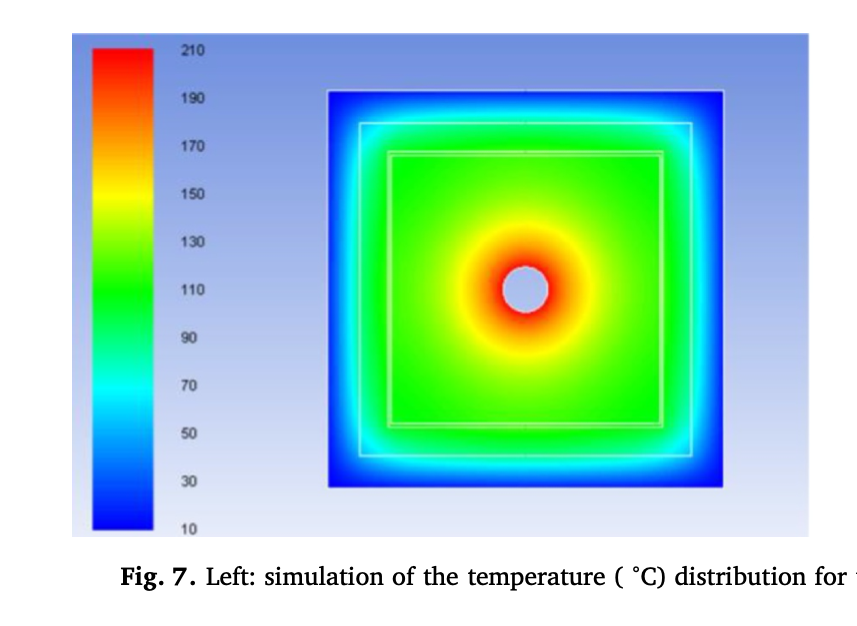

Including metal wool solves the main problem of PCM storage – at a very low cost. Despite their excellent long-duration low-cost thermal storage ability with high energy density and losses under 1% daily, PCMs are poor conductors of heat.

Including the metal wool solves this because metals like steel have excellent heat conductivity. The very fine steel fibers can conduct heat at 40 watts per meter of thickness per degree of temperature difference. This densely packed metal wool increases the thermal conductivity of the PCM by 300% without decreasing its energy density.

A heat map shows the distribution of heat in the PCM

This metal wool could also use energy from the grid to charge each storage module thermally, so it also acts as an electric heater inside the liquid PCM.

“And this is the HYBRIDplus concept we are evaluating,” she noted. “What we do in the project is to integrate metal wools in the PCM so the heat transfer coefficient is highly enhanced while at the same time, we use this metal as an electric heater to hybridize the thermal energy storage, allowing us to store excess electricity from a solar PV plant for example.”

During the next four years, real-world testing of this cascaded thermocline will drive some changes from the original concept

There have already been some changes since Prieto first proposed the idea in 2019 in Thermal energy storage (TES) with phase change materials (PCM) in solar T power plants (CSP). Concept and plant performance and the 2021 paper New phase change material storage concept including metal wool as heat transfer enhancement method for solar heat use in industry.

In these earlier papers, lower temperature melting points and PCM candidates were selected for Parabolic Trough CSP. However, the HYBRIDplus project aims at higher temperatures for super-efficient Tower CSP or standalone thermal storage. Therefore, next to be decided is which four PCM candidates to include with higher melting points from 300°C to 600°C.

Also to be decided will be the optimal arrangement of the four modules inside the tank, whether vertical or stepped diagonally. “It’s not settled exactly how it would be arranged,” she said. “Whether we need to add more piping to make the connection from the top down between each module. So, the final arrangement will depend on comparing structure versus piping; what is more expensive.”

What cascaded thermocline tanks might look like commercially

At a commercial scale, these four modules’ total size would comprise about 80% of one of today’s molten salt thermal energy storage tanks serving commercial CSP plants. This standalone thermal energy storage would store surplus renewable energy or be deployed for the many industries that need processing heat.

The research, led by the University of Seville in Spain, is being carried out by a consortium of four businesses SEICO Heizungen GMBH, Build to Zero, R2M Solution, and Deutsches Metalfaserwerk, with two other universities; KTH Royal Institute of Technology in Sweden, and the University of Lleida in Spain.

, solarpaces.org