Combining concentrated solar power with thermal storage to avoid wasting energy

In sunny locations, solar power can sometimes produce too much electricity for the grid. Australian company RayGen hopes to solve this problem by combining its hi-tech solar systems with thermal storage, as Richard Stevenson reports.

Hybrid hope RayGen’s first power plant, near Carwarp in Australia, makes use of its new technology that combines solar cells with water-based thermal storage. (Courtesy: RayGen)

Australia is renowned for its hot and sunny climate, with parts of the country seeing an average of 10 hours of sunshine a day – compared with a lowly four hours for those of us in the UK. It is perhaps no surprise then that in 2021 solar power was Australia’s biggest source of renewable energy. However, it still only made up 12% of the country’s total energy generation (renewables as a whole accounted for 29%).

So how can we increase the proportion of electricity generated by solar cells? Is it simply a matter of cutting the cost of the photovoltaic panels and increasing their availability? Unfortunately, no – the reality is more nuanced.

Solar farms are most productive in locations where the Sun beats down hard day after day, such as Australia and the south-west US. But in such places, so much energy is being generated during the middle of day that, at times, there’s too much. Owners of solar farms then have to pay the electricity grid to take away the additional energy. And if the grid doesn’t want it, the farms are forced to reduce their output or even shut down generation entirely.

To address this maddening state of affairs, new hybrid renewable energy systems are starting to appear in these locations, combining electricity generation with some form of energy storage, so that the grid only receives power when it needs it. However, while there are various storage options, they each have limitations. Lithium-ion batteries, for example, cost around five times as much as solar panels and their performance degrades with time. In hydroelectric schemes, the excess electricity would be used to pump water to higher ground, thus converting the electrical energy from the solar cells into potential energy that could be converted back when needed. But this set-up requires hilly locations, which are incompatible for solar farms because they are prone to cloud and rain. It is also prohibitively expensive to construct a solar plant in an arid location and connect it to a hydro scheme via electrical transmission lines.

One alternative to the conundrum is a patent-pending technology being developed by the Australian firm RayGen. By pairing solar cells with water-based thermal storage, this Melbourne-based company is offering what it claims is a cost-competitive system that meets the needs of grid operators.

Not just solar power

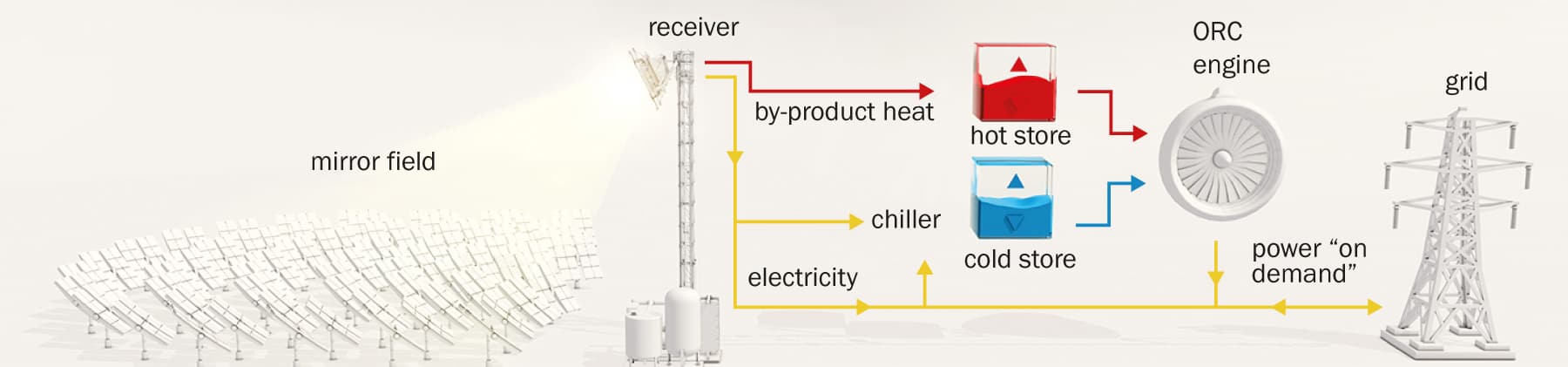

RayGen’s system consists of multiple stages and technologies (figure 1). First, a series of mirrors focuses sunlight onto a collection of solar cells at the top of a receiver tower. These cells convert the rays into electricity, which is fed into the grid, just like in a conventional solar farm. Although the focused light causes the cells’ temperature to increase, a cooling flow of water prevents them from overheating and becoming inefficient. The heat now held in the cooling circuit is transferred via a heat exchange to a secondary system that flows into a thermally insulated underground reservoir of water at a temperature of 90 °C.

When the grid needs additional electricity, this thermal store, alongside a reservoir of cold water, drives an organic Rankine cycle (ORC) engine, in which the hot water evaporates ammonia that turns a turbine to generate electricity. The ammonia is then cooled and re-condensed by the cold water to go through the cycle again. On days when there is an excess amount of solar power, that electricity can bolster the energy-storage capacity of the thermal section of the system.

RayGen claims the cost of this system is kept down because it draws on various established renewable technologies – from pit-based thermal energy storage to photovoltaics and ammonia-based turbines – and so can compete in the marketplace. “On the solar side we’re cost-comparable with utility-scale photovoltaics on a dollar-per-watt basis,” says Kira Rundel, RayGen’s commercial manager. “On the storage side, it’s similar to pumped hydro. And in terms of the cost of energy storage, because we’re just using water, it’s similar to hydro power.”

Technology test run

RayGen has almost finished commissioning its first power plant, located about a six-hour drive inland from Melbourne, near a place called Carwarp. So many solar farms have been installed in this area that on a sunny day there can be an over-supply to the grid, which gives RayGen the chance to showcase its credentials. On this site the company has constructed four of its 1 MW systems, sitting side-by-side. In addition to generating up to 4 MW of electricity from the solar cells, this facility has a 50 MWh storage capacity, and can deliver 3 MW to the grid for 17 hours via the ORC turbines.

Each 1 MW system features a field of nearly 300 “smart” mirrors, arranged around a tower-mounted photovoltaic receiver. The mirrors are able to track the position of the Sun through the day, directing light to the tower from dawn to dusk and focusing the rays by a factor of 750. As well as reducing the number of photovoltaic cells needed, and therefore the cost, magnifying the intensity of sunlight onto the receiver also delivers a valuable increase in efficiency.

The receiver itself has a 4.41 m2 active area comprising 441 solar modules, each 10 × 10 cm in size and populated with the most efficient class of commercially available solar cell. Widely used to power satellites – an application where high efficiency and a robustness to radiation are highly valued – these particular cells are made of several semiconducting materials, including germanium, gallium arsenide and gallium indium phosphide, so therefore have multiple p–n junctions. As each junction has a different absorption profile, the cells can capture most of the Sun’s full spectrum – which stretches from ultraviolet to infrared – grabbing twice as much sunlight as traditional silicon, and efficiently converting it into electricity.

With RayGen’s set-up, cell efficiency for electricity generation is around 38%, while for the modules it’s just over 35%, and receiver efficiency is nominally 32% (the exact figure depending on operating conditions). In comparison, cells made from traditional silicon would have a module efficiency of around 18–20%. While such silicon cells would save money, it would be a false economy according to RayGen’s chief research officer, John Lasich. He argues that this initial cost gain would be overshadowed by a substantial cut to electrical power generation and an inferior ratio of electricity-to-heat generation.

The role of water

RayGen also claims its technology addresses a major weakness of all traditional photovoltaic systems. Even those that use the best devices waste much of the Sun’s incident energy in the form of heat, which also raises the cell’s temperature and impairs its efficiency. In the RayGen system, however, this excess heat is used.

In each receiver, water is used to cool the photovoltaics. It is pumped up the tower, through the back of the modules and back down to the base, where a heat exchanger transfers the thermal energy to a secondary system. The re-cooled water in the initial circuit can then be pumped back up the tower to be reused.

The secondary system flows to the hot reservoir, which at Carwarp is a 17,000 m3 pit containing 90 °C water. The pit is lined with a polymer, insulated and sealed, which means that – thanks also to the very low surface to volume ratio – very little energy is lost. “If you think of it like a battery, the self-discharge is lower than a fraction of a per cent over several weeks,” says Lasich.

When the grid needs energy and the Sun isn’t shining, heat from this pit drives an ORC turbine. As ammonia is the working fluid in this closed-loop system, it has to be cooled and re-condensed after passing through the turbine, which is done with a second 17,000 m3 pit, held at a lower temperature. In hot, sunny places, such as the outskirts of Carwarp, this pit would heat up to 40 °C or more if not manually cooled. As this is only 50 °C less than the hotter pit, the efficiency of electrical generation from the ORC turbine would be no more than about 5%. So to increase that to 12–15%, RayGen cools the cold-water pit to near freezing using an industrial chiller, creating a temperature difference of around 90 °C between the two massive bodies of water. “That’s equivalent to a hydro set-up with two dams with a head of 1000 m,” says Lasich.

While 12–15% efficiency for energy generation from the turbine is not that high, no electricity is consumed in heating water to 90 °C. Electricity is only used for chilling the cold pit, and for every 1 MWh used for this purpose, 0.7–0.8 MWh is recovered when running the turbine. The chilling of the second pit enables RayGen’s energy storage system to behave just like a giant battery, according to Lasich. When the grid has more than enough energy, any excess can be used to run the chiller, which can also be powered by the electricity from RayGen’s multi-junction solar cells.

Sunny times ahead?

“The RayGen system is an interesting exploitation of concentrator photovoltaic (CPV) technology, and the storage element using water from cooling the cells is an excellent addition to the electricity generation alone,” says Geoff Duggan, who was chief technical officer at Fullsun Photovoltaics Limited in the UK, before it went into liquidation and was dissolved in 2022. He is not convinced, however, that this new approach will revise interest in CPV systems. “It has always been dogged by the costs and the inability to scale to capacities where costs will be dramatically reduced.”

RayGen is obviously more optimistic about the technology, and also says that customers ordering a RayGen system will be able to generate income from a number of different revenue streams. As well as getting paid for exporting electricity, further payments come from just being able to provide the grid with additional capacity, even if it’s not used. And on top of that, there’s a revenue opportunity from the frequency ancillary services market, because the combined solar and thermal system can respond within seconds to the demands of the grid. Rundel reckons that a RayGen system “delivers profitable and attractive commercial projects, together with our strategic partners”.

As well as signing off the 4 MW project near Carwarp, RayGen is putting together a production line to make its modules. It hopes the total number of modules produced each year will be able to generate 170 MW of power. As the number of projects in the pipeline continues to grow, this line will be expanded to greater scale.

Larger projects will also need larger systems. For example, the pits for bigger future projects will be scaled up in line with increased ORC capacity, to continue to provide 12–24 hours’ storage. RayGen expects pits at this scale to have a volume of 150,000–250,000 m3, depending on the required storage duration for a given project. One partner, Photon Energy, has already secured land in South Australia for a facility that will combine 300 MW of solar with a storage capacity of 3.6 GWh that’s capable of delivering up to 150 MW.

While initial projects are in Australia, RayGen’s ambitions extend overseas. Not everywhere in the world has the idyllic weather that a RayGen system needs, but there are opportunities anywhere with plenty of sunshine, a need for electricity, and a grid that would benefit from a flexible, fast supply and storage system.

Richard Stevenson is a science writer based in the UK and editor of Compound Semiconductor

physicsworld.com

Últimas noticias

Recibe nuestras noticias por email

Recibe todas las novedades publicadas en nuestro portal de noticias.

También te puede interesar

- 20 de noviembre de 2012|

- 21 de noviembre de 2012|

- 25 de noviembre de 2012|