Concentrated solar power is an old technology making a comeback. Here’s how it works

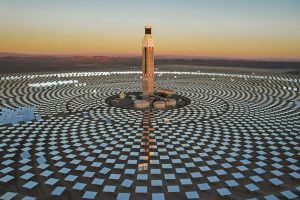

There was a time, not long ago, when the future of electricity generation looked something like the opening scene of Blade Runner 2049, with endless arrays of mirrors in concentric circles.

Concentrated solar power (CSP) uses mirrors to focus heat from the Sun to drive a steam turbine and generate electricity.

While CSP was once the great hope for replacing coal and gas-fired generation, it’s now generally considered to have been eclipsed by cheaper forms of renewable generation, like solar panels and wind turbines.

Recently, however, it’s been making a quiet comeback.

The reason for this boils down to three words that describe one of the major challenges of decarbonising the grid: overnight energy storage.

The CSIRO’s Renewable Energy Storage Roadmap, released last week, predicts that by 2050, CSP will be the cheapest way to store energy for 8–24 hours.

Developing this «medium-duration» storage is a necessary step to switching off coal- and gas-fired generators that produce most of the power we use at night.

For this reason, CSP projects are starting to gather momentum.

The Australian Renewable Energy Agency (ARENA) recently approved $65 million in funding for a Sydney-based company, Vast Solar, to build the country’s first commercial-scale CSP plant in Port Augusta, South Australia.

So how does CSP work?

And what role will CSP play in a net-zero Australia?

A technology that once rivalled solar panels

The idea of CSP is so simple that the technology hasn’t changed much in decades.

Italy built the first CSP plant in 1968, and California installed the first commercial-scale array in 1981.

At the time, solar panels were expensive and mostly used in consumer electronics, whereas CSP relied on familiar technologies, such as steam turbines.

CSP plants also looked impressive: The popular «power tower» design featured a circular field of thousands of mirrors, focusing their light on the crown of a central tower, which in some cases soared taller than 200 metres.

But then, more efficient panels and larger factories drove down the price of photovoltaics (PV), while CSP plants ran into problems with leaking fluids and dirty mirrors.

In 2019, South Australia scrapped a $650 million project to build Australia’s first commercial-scale CSP after the company behind the project revealed it could not raise funding.

«It’s been a bit of a tale of woe in Australia,» said Keith Lovegrove, director of the Australian Solar Thermal Energy Association.

«We’ve actually managed to snatch defeat from the jaws of victory a couple of times.»

As of 2021, the global installed capacity of CSP was 6.8 gigawatts, which was many hundreds of times less than the figure for photovoltaics.

But CSP is not dead. Spain, Morocco, South Africa, Israel and other countries are using CSP in their grids, while China has dozens of projects underway.

«China is the most active place at this, at this very moment,» Dr Lovegrove said.

CSP cannot generate daytime electricity as cheaply as solar PV, but it has one advantage: built-in storage.

The heat from the Sun is stored in a medium such as molten salt. When the Sun goes down, this stored heat can be tapped to drive the turbine and generate electricity.

This combination of generation and storage makes CSP «dispatchable», meaning the power can be sent to the grid when it’s needed.

«The whole point about CSP is that it’s dispatchable renewable generation,» Dr Lovegrove said.

«It’s generation you can have when you need it at night, or peak periods. It comes at a higher price because it’s got this added value and complexity.»

What is CSP’s role in the grid?

Last week, the CSIRO’s Renewable Energy Storage Roadmap report indicated the National Electricity Market (which is all of Australia except NT and WA) could require a 10- to 14-fold increase in its electricity storage capacity between 2025 and 2050.

As you can see from the graph above, most generation will be solar PV and wind by the end of this decade.

The pink bars at the bottom show dispatchable storage, which is mostly pumped hydro and large-scale lithium-ion batteries.

CSP will be competing for this dispatchable storage market.

The graph above shows the «levelised cost of storage» (the cost per megawatt-hour, factoring in everything from the cost of charging, to installation and maintenance) for up to eight hours.

According to the CSIRO’s forecasts, by 2050 CSP will be the cheapest form of this medium-duration storage.

For household energy consumers, this overnight cost of storage will directly affect how much they pay for power at night.

And if you’re planning on buying an EV, you’ll probably use more energy at night, as this is when most people charge their car (and most don’t have a household battery).

At the moment, the power we use at night mostly comes from coal- and gas-fired generation, said Dominic Zaal, director of the Australian Solar Thermal Research Institute within the CSIRO.

«But coal is exiting … and you have to replace it with something,» he said.

«[Renewable energy at night] is going to become very expensive, we believe at over $200 per MWh.»

By comparison, that’s twice the average price across the National Electricity Market late last year.

Large-scale batteries are good for smoothing spikes in demand through the day and early evening, but an expensive way of storing large amounts of energy for longer than a few hours.

«Batteries become very, very expensive after a period of time,» Dr Zaal said.

«So what are the alternatives?»

A new design for CSP

In February, ARENA announced $65 million in funding to Vast Solar to construct VS1, a first-of-a-kind 30 MW/288 MWh CSP plant in Port Augusta.

«History has proven that PV won the race to be the dominant solar technology,» said Craig Wood, the company’s CEO.

«But what’s becoming clear now is that it’s about dispatchability.»

That is, daytime power is so cheap there’s a greater premium being placed on delivering power to the grid when it’s needed, rather than when it’s plentiful.

In 2019, Vast Solar won the International Energy Agency’s technical innovation award for the world’s most innovative CSP technology.

Unlike the «power tower» designs in the Californian desert, Vast Solar’s design uses multiple, smaller towers to reduce the power lost if one tower goes down.

Parabolic mirrors, known as heliostats, track the Sun to ensure the beam of reflected light remains aimed at the receiver tower.

The heat is first stored in liquid sodium metal at 565 degrees Celsius, then in molten salt at 550C, and finally as steam to drive a turbine.

«We can spin a turbine at 538C, which is the standard temperature for a high-efficiency steam turbine,» Mr Wood said.

At 30MW, the Port Augusta plant will test and prove the design before larger plants are built.

«If you’re on-grid, it needs to be typically 100MW-plus.

«CSP gets extremely cheap once you get up to 150–200MW in size.

«At those sorts of sizes, you would expect to be building the plants with somewhere between 12–20 hours of storage.»

In February, Vast Solar also announced a merger with a US energy company in a deal valued at $US586 million, as well as plans to list on the New York Stock Exchange.

According to Mr Wood, several Australian companies are leading the world in some energy storage technologies.

«There’s a bunch of American companies that are basically trying to play catch-up,» he said.

Mixing PV and concentrated solar

In Victoria, RayGen is developing a new kind of power plant that borrows elements of photovoltaics and concentrated solar thermal technology.

Also partially funded by ARENA, its design uses a field of aligned mirrors to focus sunlight onto a tower-mounted receiver.

Unlike the Vast Solar design, this receiver has an array of PV modules, which convert sunlight directly to electricity.

The heat from the sunlight is stored at 90C in an insulated, rubber-lined reservoir.

A second pit stores water chilled to near freezing, using electricity from the grid or the solar PV receivers.

The temperature differential allows electricity to be generated using an organic Rankine cycle turbine, which transforms thermal energy into electricity.

The key to the design is the ultra-efficient PV receiver, said Will Mosley, RayGen’s chief commercial officer.

«You just need 4 square metres to make 1MW of electricity and 2MW of heat.

«It’s about 2,000 times the power density of a traditional solar panel, and twice the electrical efficiency.»

Why don’t you have one on your roof? To be economic, it needs a focused beam of sunlight, 1,000 times the usual concentration.

«The beam is strong enough to melt steel,» Mr Mosley said.

He added that the PV module generates energy at about the same cost as standard solar panels, and the array of mirrors uses about the same amount of land.

In addition to this, the system uses heat that would be otherwise wasted.

The insulated pits may lose up to 10 per cent of their thermal energy over six months.

The process of converting stored energy to electricity was about 70 to 80 per cent efficient.

«It has a similar performance to pumped hydro and can be co-located in solar renewable energy zones where long-duration energy is needed most,» Mr Mosley said.

«And it can be delivered quickly.»

But what about pumped hydro?

While CSP is still at the trial-project scale, the big investments are in pumped hydro.

Australian governments have announced about 15GW of pumped hydro energy storage, including 7GW in Queensland.

«Pumped hydro is 95 per cent of the global storage market,» said Andrew Blakers, a professor of engineering at the Australian National University.

«There’s a lot of arm-waving that we need new technologies, but the fact is you cannot grow new technology from zero to something very large in a very short time.»

Supporters of CSP argue that it would be suited to hot, dry areas where there are fewer options for pumped hydro, like in parts of Western Australia.

It could also provide storage and generation for remote, off-grid mining operations.

If that’s the case, the CSP will be a niche solution, with pumped hydro doing most of the storage.

Are there other uses of CSP?

Other uses for concentrated solar are to generate and store thermal energy for high-temperature industrial processes, or to make low-carbon «green» fuels.

Mars Petcare in Wodonga, for instance, has installed a graphite battery to store heat at 900C, as a way to reduce the factory’s gas consumption.

In that case, the heat is generated by electricity purchased from the grid.

But the heat could also be generated by a field of aligned mirrors, like with CSP. This kind of technology is known as concentrated solar thermal.

Vast Solar is currently working on a concentrated solar thermal project for a «major global food company» with a «couple of facilities on the east coast of Australia».

«We’re retrofitting CSP to displace gas in their process,» Mr Wood said.

«We’re putting in a CSP plant immediately adjacent to where they are that’s going to use the Sun’s energy to create steam to replace the gas that they’re otherwise burning.»

Dominic Zaal estimated concentrated solar thermal could serve 20 per cent of the industrial processed heat market.

«Some of the big mining entities, some of the big food manufacturing entities, they’re all looking at renewable heat now.»

Another emerging use of CSP is making «green methanol», which is made by first producing green hydrogen and then combining this with carbon dioxide.

The result is a fuel that’s easier to store and transport than hydrogen, and with a lower carbon footprint than other liquid fuels (although higher than green hydrogen). Green methanol can be used for shipping, converted into aviation fuel, or used to make plastics.

«You need the power to create the hydrogen, but you need the heat to do the green methanol synthesis,» Dr Zaal said.

«You’ve got to take a source of CO2, and smash it with the hydrogen at about 300 degrees to give you green methanol.»

The Australian and German governments are investing $40 million in Vast Solar to build a solar methanol production plant next to the Port August facility.

The proposed plant will produce 7,500 tonnes of green methanol each year, using hydrogen from an electrolyser at the site and CO2 captured from the process of making cement at a co-located facility.

«What’s emerging from our methanol project is that if you’re able to use a combination of heat plus electricity, that ends up being quite a bit cheaper than if you’re trying to do the same job with electricity alone,» Mr Wood said.

«It’s giving us some confidence that we can enter the green fuels market and be competitive with the existing black fuel prices.»