Heliostat concentration boosted by shape-shifting glass

By manipulating the shape of heliostats in real time, the optical efficiency of solar fields for tower CSP can be significantly increased, according to a paper presented at the New Mexico SolarPACES Conference: Heliostat with Automatic Shape Adjustment for High Concentration Throughout the Day, presented by Nick Didato and Roger Angel, an Oxford-educated astronomer at the Steward Observatory.

How it works

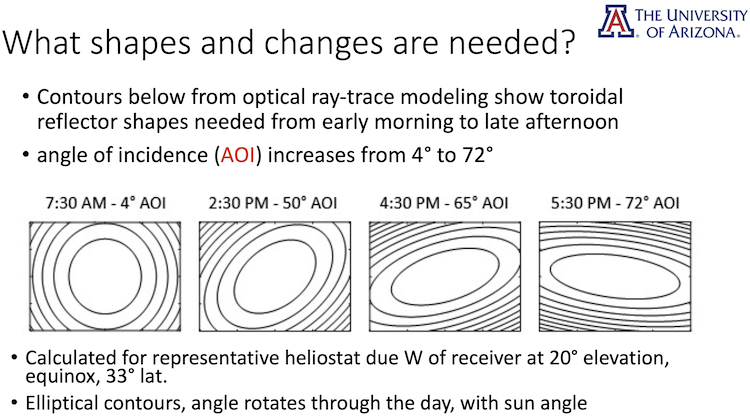

Angel has innovated the use of twisting the heliostat reflector mirror glass into the specific concave heliostat shapes that most concentrate the sun focused onto the solar receiver on the tower, at each point in the sky throughout the day.

Heliostats get a concentration boost by bending and twisting the mirror with a mechanical frame

“What we’re doing reaches the fundamental limit of optics. We’ve made the first full-scale prototype of a heliostat with twisting glass. And it works just fine,” said Angel, who has an extensive optics background and 25 years as a University of Arizona Regents’ Professor of Astronomy and Optical Sciences.

“What is unique that we’re doing is changing the heliostat shape by bending the glass. We have struts on the back of the metal frame that twist the metal frame, changing the shape of the glass connected to the frame. Nobody’s done this twisting before. But if you don’t change the reflector curve through the day as the sun is reflected at different angles, then you can’t get the highest concentration. ”

Most heliostats have a similar kind of mirror support framework at the back. However, this has not been leveraged to perform this extra focusing task by bending the glass into different shapes throughout the day to maintain a sharp focal point.

“The real trick is not simply showing a demo system at noon,” he pointed out. “To make money, a heliostat has to keep the sunlight concentrated from pretty much when the sun comes up to when it goes down again – then bending is pretty important because of all those different angles on the glass. The principles of optics say that the shape of the reflector at different times of day has to be different, and what we have worked out, I think, is the simplest way to get those different shapes: Stick the glass to a rectangular frame and twist the frame as the angle changes.”

There’s nothing special about the glass Angel uses. It’s off-the-shelf 1/8” mirror glass that comes in an industry standard for shipping, 3.3 m by 2.4 m, a standard size dictated by the width of the glass strip rolled out industrially and the height of shipping containers.

How boosting heliostat concentration affects efficiency

“The fundamentals of optics set a limit to how much you can concentrate light,” said Angel. For each of our heliostats that limit is ten times concentration at 100 m distance. That means with 100 heliostats, we can get 1,000 concentration focus, so you don’t need to have too many to get very high concentration. I think our ten times concentration all day is more than anybody’s achieved with an individual heliostat.”

The extra concentration he can achieve from each heliostat means there can be a much more compact, closer solar field in front of or around the tower.

“Suppose you want fewer than 50,000 mirrors, and people are very interested in that now,” he surmised. “In that case, the Department of Energy is now interested in smaller-scale systems, maybe only 100 meters from the heliostat to where you need the light on the receiver. Then, if you don’t change the shape during the day, as the sun moves around, you can’t get a sharp focus of the light, so you can’t get high temperature, high concentration focus.”

More concentration is needed for new smaller solar fields

Solar fuels startups like Heliogen and Synhelion are increasingly interested in more compact heliostat fields suitable for generating solar heat at high temperatures on industrial sites, like cement factories, steel works, and copper mines. High-temperature solar heat is increasingly interesting for producing solar fuels for hard-to-abate shipping and aviation, like hydrogen, ammonia, and aviation fuel.

“I think it’s the hope that thermal industrial heat may provide an avenue where CSP will be profitable,” he said. “People don’t want to set up factories that need gigawatts of heat in a huge system. So there’s interest in smaller systems at a very high temperature.”

Angel noted that this new focus on smaller systems for process heat also makes trial-and-error innovation more feasible: “When you build the huge CSP projects, they cost about a billion dollars, so you don’t have many shots to get it right,” he said.

“But if you can make smaller scale systems by twisting the heliostats, then it’s not such a crazy huge investment. And there’s an opportunity to learn from your mistakes and develop this technology, which we expect to do.”

In 2020, his team did a small all-day demo using a hexagonal heliostat and got data showing that the concentration remains extremely high all day with the bending shape. That one required three additional actuators and computer control to decide the twisting.

For the current version, the dual-axis mount is target oriented (instead of alt -azimuth), so that the twisting may be done mechanically. The first axis points to the target and the second is perpendicular to that, so the amount of twist needed to change the shape of the glass is in exact synchronization with the second axis, and may be set mechanically by two cams.

DOE funds Angel’s heliostat demo at Sandia

Now, Angel’s group has funding from the Department of Energy (DOE) to demonstrate this new mechanical version in a twisting solar heliostat in the Spring of 2024, in a joint effort with Sandia Laboratories. “So we’ll be going over there with this first model at the end of this year,” said Angel.

“We’ll compare it directly with the fixed shape ones in the spring. We will take the data and measurements; just the one heliostat to demonstrate the principles of concentration. We’ll measure everything about that image: the diameter, how much energy we use, how it varies during the day, and all the parameters you would want to model if you made a full-size system of these. And then, if that’s successful, I hope that next we would build a field of about 100 of them and get concentration of 1,000.”