Australia’s Vast Concentrated Solar Power to include green methanol demo for shipping

Methanol is used to make many chemicals, but what makes producing green methanol most interesting for the future is that the shipping industry, finally having to deal with climate emissions, considers green methanol the most viable alternative to today’s fossil-based marine gas oil.

“In the last 12 months, major international shipping companies including Maersk, CMA CGM, Cosco and others, have decided on methanol as a transition fuel,” said CEO Craig Wood of Vast, which is developing a concentrated solar power (CSP) plant in Port Augusta.

He explained why Vast plans to include a commercial reference renewable methanol facility onsite.

Maersk has already ordered 19 vessels with dual-fuel engines able to operate on green methanol.

“These big shipping lines, for all of the new-build ships that they’re buying, they’re specifying dual fuel, gas oil or methanol, because these ships last at least 30 years. So, if you’re genuinely trying to get to net zero by 2050, you need a fleet capable of burning renewable fuels. They’re currently running on marine gas oil or heavy fuel oil. They have found that it’s quite straightforward to build those boats so that they can also run on methanol.”

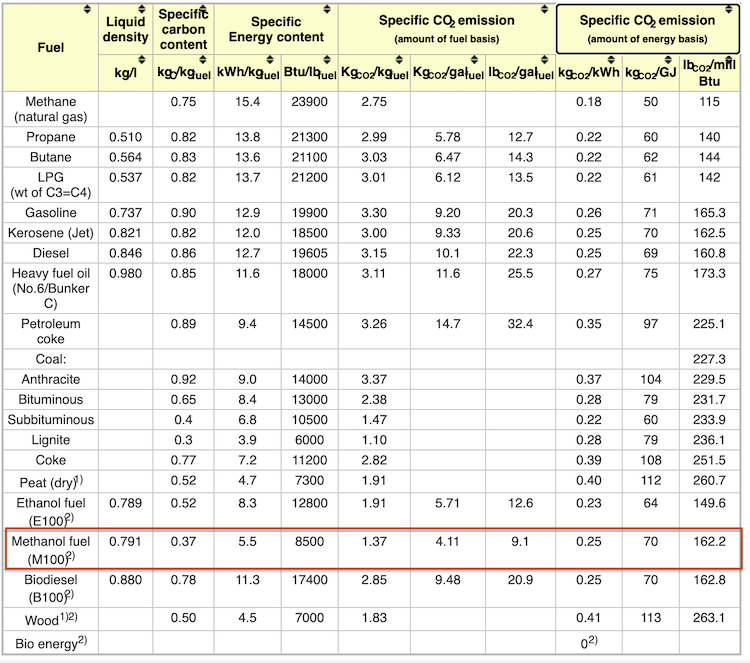

Because methanol is a liquid at room temperature like gas oil, the cost to convert land-based infrastructure and dual-fuel shipping would be lower than for alternative fuels that must be stored and transported cryogenically or at high pressures. It has a higher volumetric energy content than other options like ammonia and hydrogen.

“There’s already a methanol industry, and safely handling it is already well understood,” he pointed out. “And these boats’ engines can burn it with very little modification. So that combination of factors means that very quickly, there’ll be a significant increase in the amount of green methanol the world will need.”

Although methanol (methyl alcohol, CH3OH) has always been produced from either natural gas or coal, with the process heated and powered by natural gas, it can actually be made from any source of carbon dioxide and hydrogen and with concentrated solar thermal energy for the heat and the electricity needed. Vast proposes to utilize about 20% of the energy from their proposed CSP plant in Port Augusta to power a commercial reference scale renewable methanol refinery.

Green methanol production reduces CO2 emissions by at least half compared to grey (Fossil derived) methanol. The other half is because CO2 is still emitted when the fuel is burned aboard ship. However, among hydrocarbon fuels, methanol has comparatively low CO2 emissions.

CSP for power and heat

“We’ve always been focused on electricity, but some of these other markets where you’re using the ability to provide heat plus power could also be really interesting,” said Wood.

“Our rationale is CSP captures solar energy as heat – but then typically, you throw 55% of that energy away if you only use it to create electricity. But if you can use that heat directly, it’s extremely efficient. So, any process where you use heat and power could be much cheaper paired with CSP.”

But Vast’s award-winning claim to fame is its use of liquid sodium to facilitate solar receiver temperatures that are higher and more consistent than today’s commercial tower CSP, as proven at their demonstration plant at Jemalong which operated for 32 months until it was decommissioned in late 2020. In the next iteration, the commercial reference project VS1 in Port Augusta, they’ll store heat at approximately 550C; within the degradation risk limits for molten salts, but the heat requirement to make methanol is lower, at only approximately 200C.

This will enable that energy in the hot molten salt to be used for longer durations, providing consistent heat for solar methanol production. “If you need heat at a lower temperature, you actually get more duration of lower temperature heat than you would if you were trying to use the heat at the same temperature you store it at,” he said.

Vast recently entered into a collaboration to develop a renewable methanol refinery onsite as part of a German-Australian ARENA-funded consortium, HyGATE.

“We were approached by our German engineering partner, Fichtner, who pointed us to a combined Australian-German government hydrogen incubator called HyGATE to provide funding support for sub-commercial demonstration projects that would essentially use Australian renewable energy, such as wind or solar, to create fuels that could be transported to Germany,” Wood explained.

The methanol production comprises several different components, to deliver carbon dioxide and hydrogen, as well as the CSP heat and power, through a consortium of firms. A leading German OEM will supply a 10 megawatt electrolyzer extracting hydrogen from water. The Australian-listed green company Calix will build an electricity-based mini project onsite to heat their electric calcining process. Because furnace gases are separate, carbon dioxide off-gassing can be captured as limestone releases it.

This captured CO2 plus the hydrogen from the water electrolyzer will then be mixed in the methanol reactor to produce methanol, also supplied by a leading German OEM. Standard methanol reactors need no adaptation to process hydrocarbons generated using green technologies.

Of course, Vast must first amass the remaining finance needed to build their CSP plant at Port Augusta that will also deliver solar heat and power for this renewable methanol refining. While climate-smart firms like Calix and strategic equity partner Mabanaft already see the green writing on the wall, more such visionaries are needed to step up to make this happen.

“You either reach financial close and build something, or you don’t,” Wood noted wryly. “We have a total of up to A$175 million in funding for VS1. But we need additional equity on top of that, so we’re currently completing a capital raise. It takes three to five years to get these projects developed to the point where construction starts and we’re part-way there so we are looking to produce renewable methanol in 2026. But we think it’s an interesting market that will grow quickly, and it certainly is an interesting use for CSP technology.”